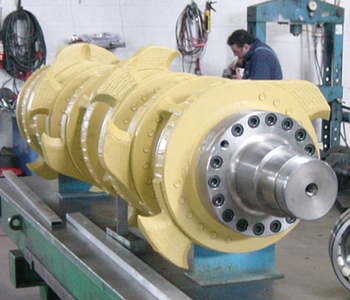

Coparm’s wrapping machine is a specific apparatus allowing the bandage with automatic plastic film of bales of waste. It is normally installed along with a continuous press to obtain in real time a packaged product of great quality and reliability. The use of these machines is introduced in the packaging of bulk products of small size, in order to prevent leakage into the surrounding environment, facilitating the transport and protecting the bale in the case of exposure to atmospheric agents.

Wrapping for waste for storage and transfer from the city to the landfill . The wrappers are used to wrap bales of waste of various kinds with the plastic film.

Waste wrapping equipment enables the storage in open areas

Wrapping avoids all the problems associated with the storage of waste and its transfer from city centers to the landfill. They are needed to allow storage in open areas. Bandaging the blocks of waste, these can remain outdoors for long periods without giving problems of leachate and odours remain isolated.The birds and rats are not so attracted by the waste and the ecosystem is not altered. The machines can wrap 20 to 50 bales / hour and over depending on the size of projects.